Polymerisation of isobutylene

| [H(OR2)2][Al(ORF)4] - a promising initiator for the polymerisation of isobutylene [Ga(arene)x][Al(ORF)4] - a promising catalyst for the polymerisation of isobutylene Literature on the polymerisation of isobutylene |

Polymerisation of isobutylene

The classic approach of polymerising isobutylene goes back to the year 1937.[1] Using the strong Lewis acid boron trifluoride BF3 in combination with a proton donating species a new way of synthesizing high molecular weight polyisobutylene (PIB) was discovered (Scheme 1).[1, 2]

![]()

Scheme 1 : Polymerisation of isobutylene.

Over the last 80 years, this approach has been augmented by novel proton-, carbocation- and metal-based systems.[3-7], [8-34], [35-52] These systems have led to a vast product lineup, ranging from low to high molecular weight PIB. Depending on its molecular weight PIB can be divided into three major groups:

- High molecular weight PIB (Mn > 200 000 g mol-1), a rubber like and physically harmless compound, has gradually substituted natural chicle as the main chewing gum base.[53]

- Medium molecular weight PIB (Mn = 40 000 - 85 000 g mol-1), a highly viscous liquid with an excellent barrier against moisture and various gases, is mainly used as an adhesive or in sealants.[41] [48]

- Low molecular weight PIB (Mn = 1 000 - 2 300 g mol-1), a honey like, colourless liquid, is an essential additive for lube oils and fuels.[54-88]

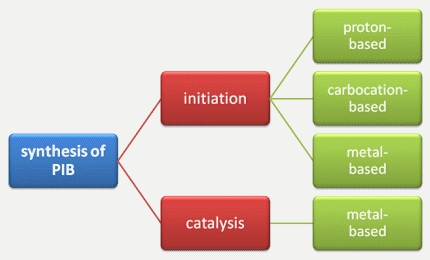

Coming back to the synthesis of PIB, both proton- and carbocation-based systems solely function as initiators. Metal-based systems however can either initiate or catalyze the polymerisation of isobutylene (Scheme 2).

Scheme 2 : Different methods of synthesizing PIB.

Up to this day most syntheses of PIB, including the industrial scale ones, show a lack in at least one point. May it be low reaction temperatures down to –100 °C, dichloromethane as a carcinogenic and water-hazardous solvent, or relatively high concentrations of the initiating or catalyzing species – all these factors sum up to a negative economic and environmental balance. Thus, current applied research focuses on improving established production methods.[89-91] More fundamental research however, addresses this problem by designing novel initiator/catalyst systems that enable a more economical and environmental friendly synthesis of PIB.

[H(OR2)2][Al(ORF)4] - a promising initiator for the polymerisation of isobutylene

[Ga(arene)x][Al(ORF)4] - a promising catalyst for the polymerisation of isobutylene

Literature on the polymerisation of isobutylene